Size: 37 47 57 67 77 87 97 107

137 147 167 177 187

Transmission Ratio:1.3~289.74

input Power :0.12-160kw

0utputTorque :3.5~23200 N.m

Transmission Ratio:5.36~200

Input Power :0.12-200

0utputTorque :10-62800 N.m

Size:37 47 57 67 77 87 97 127 157

Transmission Ratio:6.8~288

Input Power :0.12-200kw

0utputTorque :3.5~21700 N.m

4 types:RC01 RC02 RC03 RC04

Power :0.12-4KW,

Ratio: 3.66-54,

Torque max :120-500Nm.

UNIVERSAL SPEED REDUCER

ratio 1/5-1/60

SINGLE SPEED REDUCER ratio

1/5-1/60

1.1 Stage(Ratio 5):B05, C05, D05,

E05,F05,G05,HO5, J05

2.2 Stage(Ratio 13/20):B13/20,

C13/20,D13/20,E13/20,F13/20,

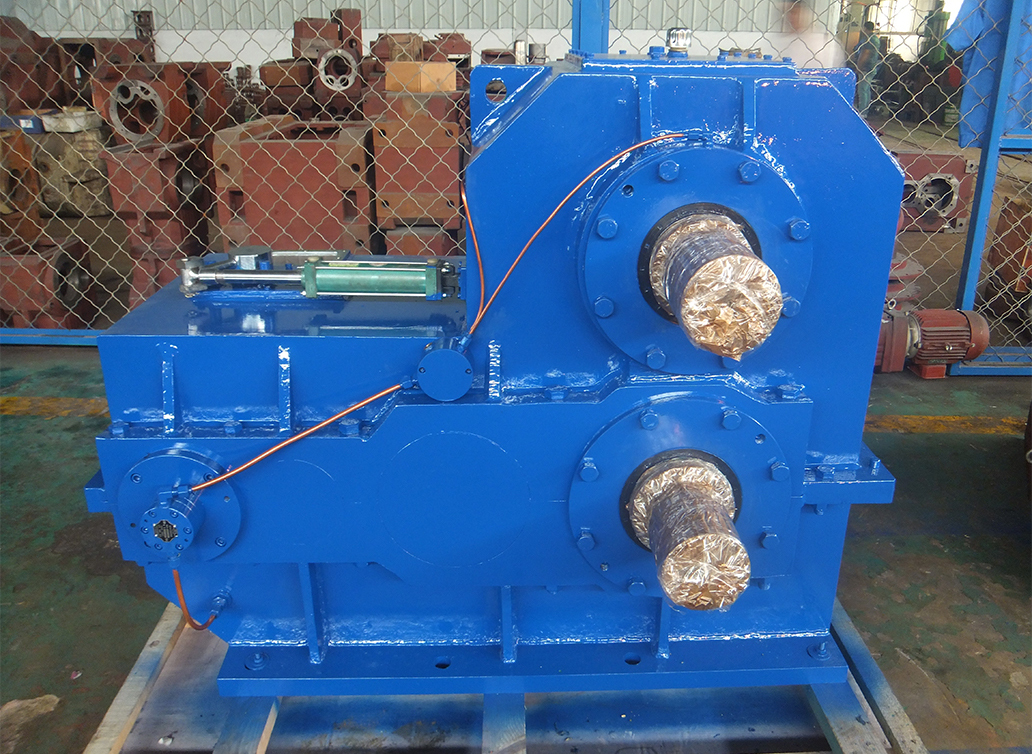

Output Speed: 1.7-1200rpm/Min

Outputtorque: 470000nm Up To

470000nm

Motor Power: 2.52-5366kw

Output Speed:0.19-60r/Min

Motor Power:0.4-1293kw

Mounted Form:Foot-Mounted And

Flange-Mounted Monting

Size: NMRV/NRV (030 040 050

063 075 090 110 130 150)

Ratio:5 7.5 10 15 20 25 30 40 50

60 80 100

Size :TA/XG30,TA/XG35

TA/XG40,TA/XG45

TA/XG50, TA/XG60.

TA/XG70,TA/XG80,

TA/XG100, TA/XG125

We have a professional team to ensure that we provide you consultation and drawing design services quickly.

The production of reducers requires various types of metal materials, such as cast iron, steel, etc., and the raw materials must be prepared first.

Read More

The parts of reducers are usually processed by multiple processes such as casting, forging, and machining.

Read More

After the parts are processed, they need to be assembled. During the assembly process, the following aspects should be paid attention to:

Read More

After the reducer is assembled, the following aspects should be paid attention to during the debugging process:

Read More

In the production process of the reducer, attention should be paid to product quality control, and a scientific quality assurance system should be formulated to ensure the stable quality of the product.

Read MoreWith quality as its core, our company has ISO9001 quality management system certification.

Read More